4. NTC custom code¶

4.1. Code Implementation¶

The first part is a check if P0_07 is connected to R1//NTC. If P0_07 is not connected and left floating, it is possible that the 2 comparators are in a state indicating that R1 and NTC are connected correctly (which they are not). Therefore, P0_07 is put as GPIO-high and P1_00 is put as GPIO input, to check the (high) state of P0_07. If P0_07 is not connected (or R1 is missing/not connected), a false is reported and the case exits.

In the second part, P1_00 is put as GPIO-high to feed the R1/NTC network and P0_07 is put as GPIO input. By enabling the charger and the charger clock, the TBAT reference ladder network and the 2 comparators are enbaled (see Fig.2). By reading the state of the 2 comparators in the [CHARGER_STATUS_REGISTER], a check can be made if R1 and NTC are connected (or not) or short-circuited.

The implementation in the hci_custom_action() function is as follows:

void hci_custom_action(dgtl_msg_t *msg)

{

plt_cmd_hci_custom_action_t *cmd = (plt_cmd_hci_custom_action_t *) msg;

dgtl_msg_t *msg_evt;

plt_evt_hci_custom_action_t *evt;

msg_evt = init_response_evt(&cmd->hci_cmd, sizeof(*evt));

evt = (plt_evt_hci_custom_action_t *) msg_evt;

switch(cmd->custom_action)

{

case (0xAA):

hw_gpio_pad_latch_enable(HW_GPIO_PORT_0, HW_GPIO_PIN_7);

hw_gpio_configure_pin_power(HW_GPIO_PORT_0, HW_GPIO_PIN_7, HW_GPIO_POWER_V33);

hw_gpio_configure_pin(HW_GPIO_PORT_0, HW_GPIO_PIN_7, HW_GPIO_MODE_OUTPUT,

HW_GPIO_FUNC_GPIO, true);

hw_gpio_set_pin_function(HW_GPIO_PORT_1, HW_GPIO_PIN_0, HW_GPIO_MODE_INPUT_PULLDOWN,

HW_GPIO_FUNC_GPIO);

hw_gpio_pad_latch_disable(HW_GPIO_PORT_0, HW_GPIO_PIN_7);

if (!hw_gpio_get_pin_status(HW_GPIO_PORT_1, HW_GPIO_PIN_0)) /* Check P0_7 - P1_0 resistor & NTC connection */

{

evt->custom_action = 0;

break;

}

hw_charger_set_clock_mode(true); /* Enable charger FSM */

hw_charger_set_analog_circuitry_operating_mode(true);

hw_gpio_configure_pin_power(HW_GPIO_PORT_1, HW_GPIO_PIN_0, HW_GPIO_POWER_V33);

/* ReConfigure the pins. */

hw_gpio_pad_latch_enable(HW_GPIO_PORT_0, HW_GPIO_PIN_7);

hw_gpio_set_pin_function(HW_GPIO_PORT_0, HW_GPIO_PIN_7, HW_GPIO_MODE_INPUT, HW_GPIO_FUNC_GPIO);

hw_gpio_pad_latch_enable(HW_GPIO_PORT_1, HW_GPIO_PIN_0);

hw_gpio_configure_pin(HW_GPIO_PORT_1, HW_GPIO_PIN_0, HW_GPIO_MODE_OUTPUT, HW_GPIO_FUNC_GPIO, true);

hw_gpio_pad_latch_disable(HW_GPIO_PORT_1, HW_GPIO_PIN_0);

hw_gpio_pad_latch_disable(HW_GPIO_PORT_0, HW_GPIO_PIN_7);

hw_clk_delay_usec(1000);

char tbat_main = REG_GETF(CHARGER, CHARGER_STATUS_REG, MAIN_TBAT_COMP_OUT);

char tbat_hot = REG_GETF(CHARGER, CHARGER_STATUS_REG, TBAT_HOT_COMP_OUT); /* Check charger comparator status */

if (tbat_main & !tbat_hot)

{

evt->custom_action = cmd->custom_action;

}

else

{

evt->custom_action = 0;

}

hw_charger_set_clock_mode(false); /* Disable charger FSM */

hw_charger_set_analog_circuitry_operating_mode(false);

hw_gpio_set_pin_function(HW_GPIO_PORT_1, HW_GPIO_PIN_0, HW_GPIO_MODE_INPUT, HW_GPIO_FUNC_GPIO); /* Reset pin to input */

break;

default:

{

evt->custom_action = cmd->custom_action;

break;

}

}

dgtl_send(msg_evt);

}

4.2. Code Integration¶

In order to integrate the custom (NTC) code in the PLT firmware the following steps need to be taken:

- As described in the Getting started, download and instal the latest SmartSnippets Studio and the latest SDK.

- In the following steps, a couple of changes will be made to the SDK and it is therefore advisable to start with a clean installation and not mix up with a regular application.

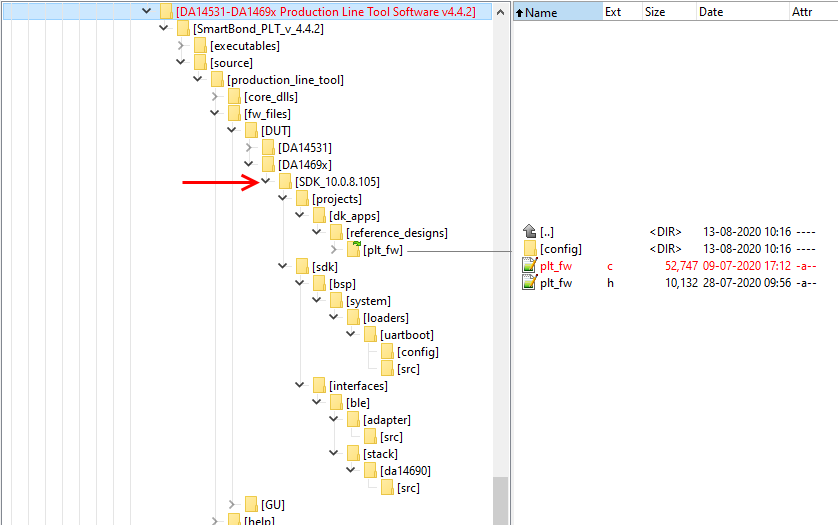

- In the PLT software there is a directory called SDK_10.0.8.105. Copy all the files in the SDK_10.0.8.105 subdirectory over the original SDK.

- In the subdirectory SDK_10.0.8.105->projects->dk_apps->reference_designs->plt_fw, there is the file plt_fw.c with the original hci_custom_action() function. Copy and paste the new hci_custom_action() function (see Code 3 above) over the original function.

- There are 2 new functions in Code 3 which needs to be declared in the same plt_fw.c file:

hw_charger_set_clock_mode()

hw_charger_set_analog_circuitry_operating_mode()

- Add the following 2 functions just before the function static bool plt_check_gpio() (at line 155)

__STATIC_INLINE void hw_charger_set_clock_mode(bool mode)

{

GLOBAL_INT_DISABLE();

REG_SETF(CRG_SYS, CLK_SYS_REG , CLK_CHG_EN, mode); /* Enable/Disable charger clock */

GLOBAL_INT_RESTORE();

}

__STATIC_INLINE void hw_charger_set_analog_circuitry_operating_mode(bool mode)

{

REG_SETF(CHARGER, CHARGER_CTRL_REG, CHARGER_ENABLE, mode); /* Enable/Disable charger block */

}

- Compile the code for RAM execution.